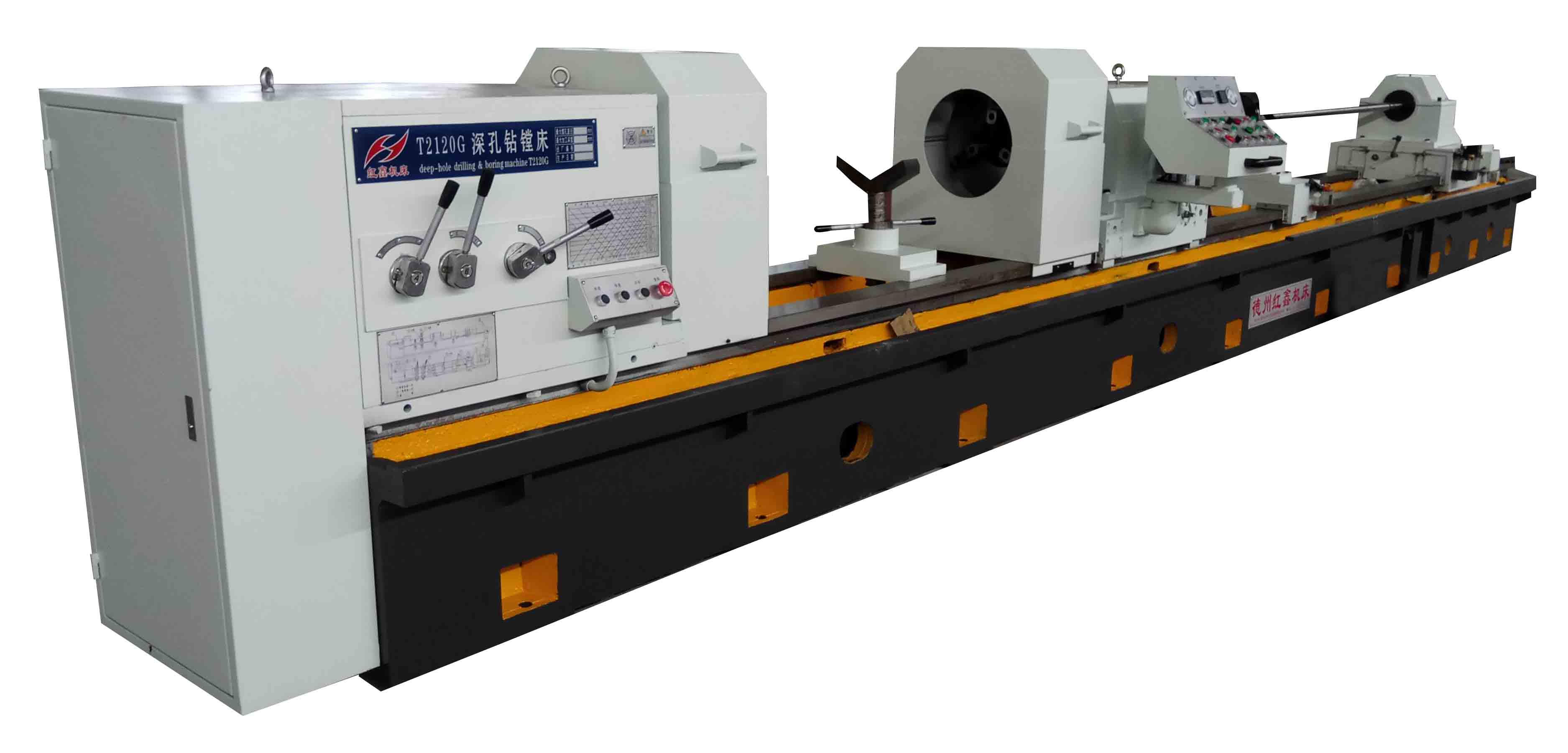

Deep Deep hole drilling and boring machine T2120G

The machine is specialized in machining cylindrical deep-hole workpieces, such as spindle holes for machine tools, various mechanical hydraulic cylinders, cylindrical through-holes , blind holes and stepped holes,.The processing accuracy can be up to IT7 ~ IT8 or above, the surface roughness can reach Ra0. 4μm. The machine tool can not only undertake drilling and boring, but also can perform burnishing processing. When boring, the pressure head is used for oil supply, and the cutting chips is discharged to the chip pipe at the end of bed through the cutting area. When drilling, the internal chip removal method (BTA method) is adopted, that is, the pressure head supplies oil, and the cutting chips is discharged from the inside of the drill pipe to the discharge bucket at the back of the bed through the cutting zone. The machine tool adopts PLC control or numerical control. The reciprocating movement of the pressre head and the feed carriage are controlled by servo motor, which can meet the needs of various deep hole machining processes. The machine tool adopts double rectangular guide rack ,the rack and pinion transmission mode to ensure the accuracy and rigidity of the feed drive in ultra-long motion. A protective cover is installed on both sides of the bed, and an on-ground oil tank is used to improve the operating environment.

This machine is a convenient, efficient and environmentally friendly machine tool.

TECHNICAL DATA | T2120G、T2120G/1 |

The range of drilling diameter | φ40~80mm |

The range of boring diameter | φ60~200mm |

The range of boring depth | 1000-15000mm |

Height from spindle center to bed | 400mm |

Workpiece clamped dia.range | φ60-φ300mm |

The diameter of chucks | φ400 |

Range and kinds of spindle speed | 60-1000r/min 12step |

The power of main motor | N=22KW |

Range of feeding speed | 5-2000mm/min |

Feed motor power | N=5KW AC servo |

Cooingl pump motor power | N=7.5KW |

Rated working pressure of hydraulic system | 2.5Mpa |

The Flow of cooling system | 200L/min two group |

Machine precision:

Roundness……………………………………………≤0.02㎜

Cylindricity…………………………………………≤0.035/500㎜

Machining precision…………………………………………ⅠT8~ⅠT10

Rounghness(drilling)…………………………………≤Ra3.2~12.5μm

Rounghness(boring) ……………≤Ra1.6~3.2μm(depending on workpiece material)

Rounghness(burnishing)………………………………≤Ra0.4μm

Straightness less than 0.15/1000

Hole deviation ≤0. 5/1000

Machining efficiency:

cutting speed :normally 50-100m/min

Feed speed ; normally 10-100mm/min

Maximum stock removal when boring:not bigger than 20mm